Utter’s polypropylene rolled depth filter is made of continuously rolled PP microfiber, for a total of 56 layers. The outer layers are constructed of graded pore size while the inner layers are stable pore size. This construction provides large filtration area, high efficiency and high dirt holding capacity, it’s service life is quadruple longer compare to normal polypropylene melt blown filter.

Highly recommended for pigment-based inks, ceramic inks, and disperse ink jet inks filtration.

Features and Benefits

- Microfiber media is used to increase dirt holding capacity, life time, it ensures high filtration efficiency.

- Made of 56 layers of continuously rolled polypropylene microfiber, it provides high filter area for a filtration efficiency of 99.8%.

- Good oil-absorption effect for ink filtration composition for items such as resin, solvent, and other additives.

- All polypropylene construction yields excellent compatibility with most ink chemistries. Inner PP core increases filter pressure endurance capability.

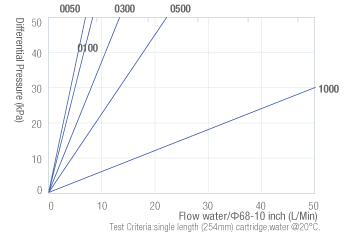

Performance

Material of Construction

| Filter Media | Rolled Polypropylene Microfiber |

| Support Layer | Polypropylene |

| Core | Polypropylene |

| O-Ring | Silicone, EPDM, Viton, PFA/Viton |

Operating Conditions

| Max.Temperature | 80℃ |

| Max.Differential Pressure | 4.0 bar / 21℃ 2.1 bar / 80℃ |

| Code | Removal Ratings | End Cap | Nominal Length | O-ring Material |

| MBR | 0.1 = 0.1μm 0.3 = 0.3μm 1 = 1μm 2 = 2μm 3 = 3μm 5 = 5μm |

Blank = DOE 3 = 222/Fin 4 = 222/Flat 6 = 226/Flat 7 = 226/Fin |

05 = 5″ 10 = 10″ 20 = 20″ 30 = 30″ 40 = 40″ |

S = Silicone E = EPDM V = Viton |