Feature

- Hydrophobic PVDF membrane for gas and solvents sterile filtration

- Absolute rating, filtration effective is ≥99.99%, minimum micron is 0.1μm

- Wide chemical compatibility, low protein binding

- 100% integrity test

Application

- Fermentation air filtration

- Tank vent

- Compressed air

- Sterile process gases

- Ultrafine particles existed in air

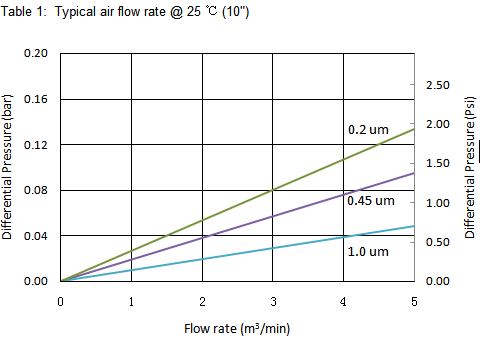

10″ Hydrophobic PVDF Filter Cartridge Flow Rate

| Construction Material | Filter Media | Hydrophobic PVDF membrane |

| Support Layers | Polypropylene | |

| Micron Rating | 0.1, 0.2, 0.45, 0.65, 1.0, 3.0μm | |

| Inner Core | Reinforced Polypropylene | |

| Outer Cage & End Caps | Reinforced Polypropylene | |

| O-ring | Silicone, Nitrile, EPDM, Viton, Teflon | |

| Dimensions | Outer Diameter | 69mm (2.75″) |

| Inner Diameter | 33mm (1.30″) | |

| Length | 5″, 10″, 20″, 30″, 40″ | |

| Filtration Area | 0.65㎡ per 10″ | |

| Operating Conditions | Normal Operating Temp. | Up to 65℃(℉) |

| Max. Operating Temp. | 90℃(194℉) at △P≤1.0bar(14psi) | |

| Normal Flow Direction | 4.2bar(60psi) at 25℃(77℉) | |

| Reverse Flow Direction | 2.1bar(30psi) at 25℃(77℉) | |

| pH Range | 1~13 | |

| Sterilization | Steam sterilization for 30 minutes at 135℃(275℉) cumulative time: 50 hours | |

| Cartridge Safety | Endotoxin | ﹤0.25 EU/ml |

| Extractables | 0.03g/10″ |

| Type | Micron Ratings | Filter Media | Length | O-ring | End Cap Option |

| FPVDF | 01 – 0.1μm 02 – 0.2μm 045 – 0.45μm 1 – 1μm |

F – Hydrophilic PVDF | 05 – 5″ 10 – 10″ 20 – 20″ 30 – 30″ 40 – 40″ Other customized sizes |

S – Silicone E – EPDM V – Viton W – Teflon encapsulated viton |

0 – flat gasket DOE 5 – 2-222 flat 6 – 2-226 flat 8 – 2-222 fin 9 – 2-226 fin |