Feature

- Combination of highly adsorptive and mechanical retention for effective clarification

- High dirt holding capacity and excellent flow performance

- Suitable for the removal of colloids, lipids, protein aggregates and particles

- Glass fiber or PP prefilter layer is available for higher dirt holding capacity and longer service life

- Good oil resistance, wide chemical compatibility

- Economical and ideal choice for protection of final membrane filters

Application

- Clarification of wine, spirits, fruit juices, soft drinks or other beverages

- Fine chemicals including reagent, inks and paints

- Colloids and viscous contaminants removal in pharmaceuticals, as vaccines, culture media

- Clarification of cosmetics

- Kinds of lubricating oil and hydraulic oil clarification

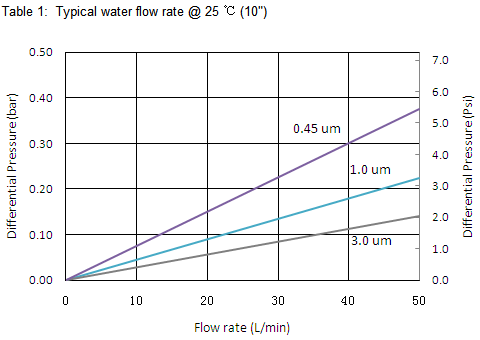

10″ GF Pleated Filter Cartridge Flow Rate

| Construction Material | Filter Media | Glass Microfiber |

| Support Layers | Polypropylene | |

| Micron Rating | 0.2, 0.45, 1.0, 3.0, 5.0μm | |

| Inner Core | Polypropylene | |

| Outer Cage & End Caps | Polypropylene | |

| O-ring | Silicone, Nitrile, EPDM, Viton, Teflon | |

| Dimensions | Outer Diameter | 69mm (2.75″) |

| Inner Diameter | 33mm (1.30″) | |

| Length | 5″, 10″, 20″, 30″, 40″ | |

| Filtration Area | 0.5㎡ per 10″ | |

| Operating Conditions | Normal Operating Temp. | Up to 60℃(℉) |

| Max. Operating Temp. | 85℃(185℉) at △P≤1.0bar(14psi) | |

| Normal Flow Direction | 4.2bar(60psi) at 25℃(77℉) | |

| Reverse Flow Direction | 2.1bar(30psi) at 25℃(77℉) | |

| pH Range | 1~13 | |

| Sterilization | In-line steam sterilization is not recommended Flush with hot water at 82℃(180℉) for 30 minutes |

|

| Cartridge Safety | Endotoxin | ﹤0.25 EU/ml |

| Extractables | 0.03g/10″ |

| Type | Micron Ratings | Length | O-ring | End Cap Option |

| GF | 01 – 0.1μm 02 – 0.2μm 045 – 0.45μm 1 – 1μm |

05 – 5″ 10 – 10″ 20 – 20″ 30 – 30″ 40 – 40″ Other customized sizes |

S – Silicone E – EPDM V – Viton W – Teflon encapsulated viton |

0 – flat gasket DOE 5 – 2-222 flat 6 – 2-226 flat 8 – 2-222 fin 9 – 2-226 fin |